PRODUCTS

Product navigation

About Us

Qingdao Xiangmao Machinery Manufacturing Co., Ltd. is a small-scale enterprise that integrates scientific research, production, installation, and sales. It is a comprehensive company that integrates metal surface cleaning equipment, sand treatment equipment, molding and core making equipment, and environmental dust removal equipment. The company is located in Huangdao District, Qingdao, with convenient and efficient water, land, and air transportation, and a superior geographical location.

Contact Us

Hook type shot blasting machine

Introduction:

Hook type shot blasting machine is mainly used for surface cleaning and strengthening of steel structural parts, castings, aluminum alloy parts and other parts. Widely used in casting, forging machinery, steel and other industries.

Hook type shot blasting machine is mainly used for surface cleaning and strengthening of steel structural parts, castings, aluminum alloy parts and other parts. Widely used in casting, forging machinery, steel and other industries.

Hook type shot blasting machine is mainly used for surface cleaning and strengthening of steel structural parts, castings, aluminum alloy parts and other parts. Widely used in casting, forging machinery, steel and other industries.

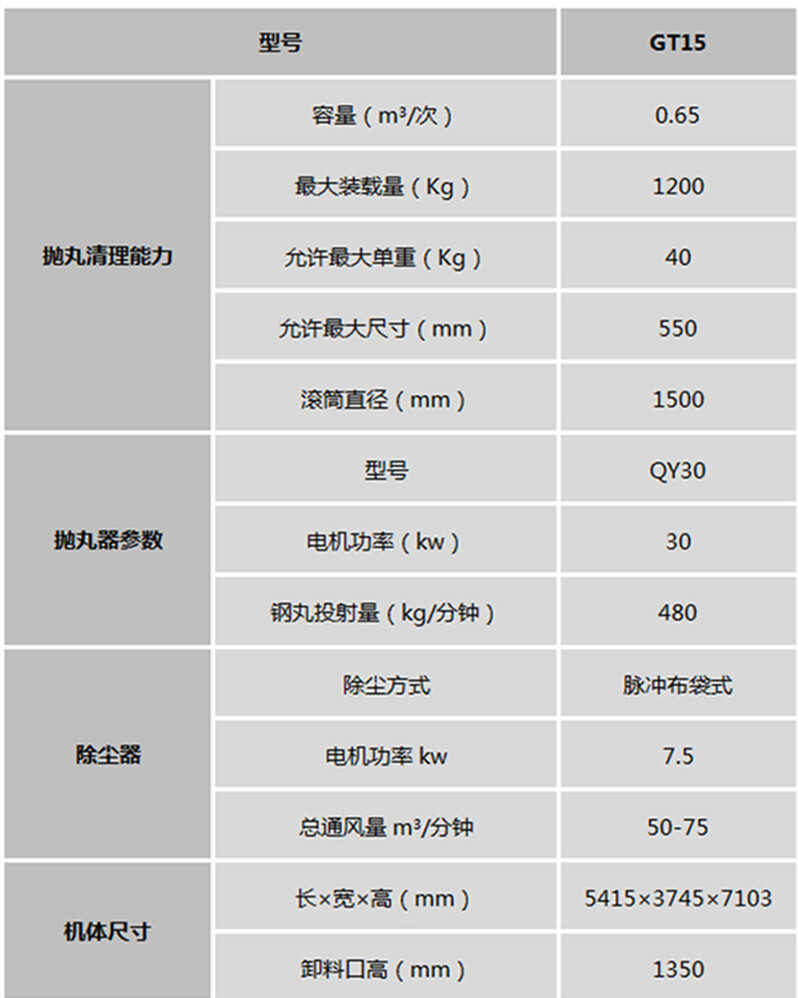

Product Parameters

More efficient:

This machine adopts a more advanced drum mechanism. During the shot blasting cleaning process, while the drum rotates, the hydraulic system pushes the drum to shake up and down, adjusts the inclination angle of the drum, and shortens the cleaning time and improves the cleaning effect of the castings by improving the mixing efficiency and uniformity of the castings inside the drum. This is one of the characteristics of the advanced design of this machine.

As the core device of the shot blasting cleaning machine, this machine is equipped with a QY30 high-efficiency shot blasting wheel, which brings higher sand blasting output with greater power, achieving the same goal and effect.

The pellet sand circulation separation system of this machine adopts a more advanced and professional design, which can ensure efficient separation of pellets, sand particles, and dust during the casting cleaning process. After cleaning, the castings unloaded are almost free of pellets and sand dust. Due to this characteristic, this machine is commonly used in conjunction with jaw crushers. After cleaning by this machine, the casting sprue can be directly fed back into the crusher for regeneration.

Lower operating costs:

The protective plate and blades of this machine's shot blasting machine are made of high chromium wear-resistant cast iron, with a chromium content of 20%. The blades, directional sleeves, and shot wheels are precision cast by wax grinding. The drum adopts a cast steel manganese 13 inner liner with a simple design. The inner liner of the drum can usually last for more than 2 years, greatly reducing the cost of use and maintenance.

Higher degree of automation:

The whole machine is controlled by PLC programming, and users only need to input the working time parameters on the LCD screen to perform automatic loading and unloading of materials and complete casting cleaning and dust removal work with one click.

Widely applicable:

This machine is used as the inner liner of the cleaning room for casting and forming, with smooth inner walls. The castings are not easily damaged during the rolling and mixing process.

Product Application

Factory Display

Contact Us

Product Recommendation